About the lab

All laboratory equipments comply with domestic and European standards and are used in the testing of all kinds of automobile spring products and rail industries.

According to the agreement between the National Standard Organization and Pars Fanar Company, according to the testing facilities available in this company and the approval of the qualification by the Standard Organization, the relevant certificate was issued.

Based on this certificate with document number (111/208/R), Pars Fanar Company is proud to perform and approve all kinds of quality tests on car springs and railway industries as a partner of the National Standard Organization.

Laboratory services of Pars Fanar company (collaborator of National Standards Organization of Iran)

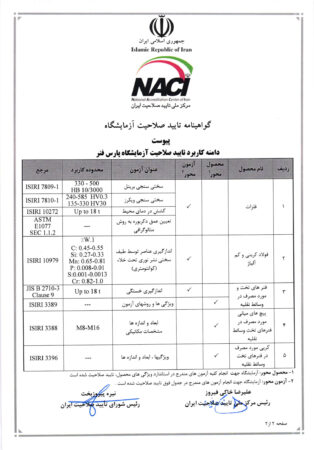

Based on the "Certificate of Accreditation of Collaborating Laboratory", Pars Fener Company's laboratory is authorized to conduct quality tests and issue standard approval in the following cases:

1. Tests of flat springs used in vehicles with national standard 3389

- Dimensions and tolerances of spring layers

- Dimensions and tolerances of the middle hole of the spring layers

- Dimensions and tolerances of the assembled spring, including:

-

- Arch height test

-

- Spring length test

-

- Eye width test after stoning

-

- Eye axis deviation test

-

- Metal bush inner diameter test

-

- Eye inner diameter test (after using the bush)

-

- Assembled spring width test

- Dimensions of the central navel

- Specifications of test cases (determination of chemical composition)

- Brinell hardness test

- Appearance test

- Decarbonization depth test

- The test to determine the characteristics of the spring, including:

- Arch height

-

- eight under specified force

-

- Spring constant coefficient

2. Tests of middle screws used in flat springs of vehicles with national standard 3388

- Middle screw dimensions (dimensions and sizes)

- Mechanical specifications of intermediate screws, including:

-

- Tensile test (determination of ultimate tensile strength - determination of yield strength - resistance test under proof load)

-

- Test to determine the chemical composition of the middle screw

-

- Vickers hardness test

-

- Deckerburg depth test (microscopy and Vickers microhardness method)

3. U Bolt tests used in vehicle flat springs with national standard 3396

- U Bolt dimensions and its accessories

- The specifications of the steels used in U Bolt include:

-

- Test to determine the chemical composition of U Bolt

-

- U Bolt tensile test (determination of final tensile strength - determination of yield strength - determination of the percentage of relative length - determination of the percentage reduction of the cross-sectional area - strength test under proof load)

4. Brinell hardness test with ASTM E10 global standard

5. Tensile test with ISIRI 10272 international standard

6. Material analysis with ASTM E415 global standard

7. Vickers hardness test with ASTM E384 global standard